FLEXII Series Grain Drill

TRUAX FLEXII GRAIN DRILLS

FLEXII Series Grain Drills feature the Jumbo sized grain box and the legume or small seed box. Planting widths are available from 5.3 ft. with model FLXlI-88G for smaller seedings up to 15 ft. with model FLXlI-822G for seeding larger production fields.

Precise Seed Placement in Various Conditions

- The Jumbo Grain box has a capacity of two bushels per foot of box length and has the same cool season/grain agitator and fluted feed cups as the FLEXII Series Grass Drill.

- The small seed box features row dividers and fluted feed cups.

- Seed delivery and placement in the soil is completed through the double disc furrow openers with depth bands and the independent press wheel.

- Planting can be done under various conditions from a well-prepared tilled seedbed to the toughest no-till conditions when equipped with no-till coulter units.

- Lock out hub is standard equipment on all FLXII Grain Drills.

Truax FLEXII Series Grain Drills With Dual Rear Transport Wheels

The Truax Rear Transport Wheels are the answer for moving wider drills on narrow roadways, especially when meeting oncoming traffic. The dual wheels remain on the road surface while the end of the drill hangs over the shoulder and ditch.

The Truax Rear Transport Wheels are the answer for moving wider drills on narrow roadways, especially when meeting oncoming traffic. The dual wheels remain on the road surface while the end of the drill hangs over the shoulder and ditch.

Narrow, crowned road centers are no linger a challenge with the 12 – 14 inches of ground clearance.

This feature can also be a real advantage when crossing swales, ditch bottoms, and traveling field roads.

After obtaining necessary travel permits and when other conditions apply, the drill equipped with Dual Rear Transport Wheels are easy to load on trailers with the transport wheels rolling up trailer ramps.

Get productive seed-to-soil placement – and save valuable time.

The FLEXII Series Drill handles field and seed bed variability – changing from the no-till drill configuration to drilling a prepared conventional seed bed – on the go. With the simple movement of a hydraulic lever, you save time and achieve productive seed-to-soil placement.

5-Speed Derailleur

5-speed derailleur controls output from the fluffy seed box.

Output Reduction Mechanism

Back gear output reduction for lower seeding rates from all seed boxes.

Drive Wheel Disengagement

Lock-out hub disengages driveshaft during transport.

Digital Acre Meter

When the acre meter is easily accessed, it gets used on a regular basis. Find the OTG’s accurate meter mounted on the end of the drill for easy reading – no more climbing onto the drill, looking for it next to the clutch.

Independent Slide Lever

Slide lever sets openings for fluted feed cups of small seed box and cool season/grain box.

Staggered Double-Disc Openers

Staggered double-disc openers and staggered no-tills provide trash clearance and eliminate plugging.

- Seed from all boxes is delivered between the double disc openers. The rolling disc opener carries the seed into the soil for proper placement and optimal seed-to-soil contact.

- Truax EZ-Off Depth Bands on every disc control planting depth. Four sizes are available to accommodate planting depths of different crops.

Soil Scrapers

Scrapers on the disc openers and the depth bands prevent moist soil from building up, compromising planting depth and seed placement.

Scrapers are located:

- On the outside surface of the discs.

- Inside between the double discs.

- On the face of the depth band.

Press Wheel

Independent movement of Truax press wheels firms soil around the seed without affecting operating depth of the planting units.

Press wheel frame provides clearance to pass residue through without bunching or plugging.

Trouble Free Seed Flow

The Truax straight line drop design keeps the seeds moving from the seed boxes to the Drill openers.

- Consistent delivery of seed to the openers.

- Eliminates plugged seed passages.

Truax Drills offer maximum control of seeding rate.

- Independent adjustment for fine tuning each seed box output.

- Simple derailleur speed changer sets output of fluffy seed.

- Optional output reduction kit for low seeding rates from all boxes.

FlexII Grain Drill Specifications

TRUAX – the global leader in the manufacture of drills and planters to sow native grasses, legumes and grains has set the standard for drill features to meter and place these seeds in order to achieve optimal establishment. When reviewing the features of different brands of drills to meet your specific needs be sure to include the following which are common to all Truax drills and planters: Including the On The Go (OTG Series), Flex II Series, Trillions, and Pull Broadcasters.

COMMON TO ALL TRUAX DRILLS

- An optional Output Reduction Kit is available to reduce seeding rates for specialized applications including low rate CRP mixes.

- Tapered roller bearings with integral rubber seal on rear bearings used on all no·till coulters.

- Separately metered seed boxes for grains, small seed and legumes, and a third box for fluffy native species.

- Depth of planting controlled by metal depth bands on all planting discs.

- Digital acre meter strategically placed on end of drill for easy access.

- Ground clearance of disc blades when in transit will be 10″ or more, press wheel clearance to be 14″ or more.

- Optional 3″ x 16″ smooth crown leading press wheels that are interchangeable with the leading no-till.

- Trouble free delivery of all seeds from the seed boxes to the drill openers. This is accomplished through large seed boots and by maintaining a vertical straight-line flow in the fluffy seed boot, a nearly vertical drop from the cool season/small grain box, and a smooth tube from the small seed box.

- Seed from all seed boxes is delivered between the double disc openers. The rolling disc opener carries the seed into the soil for proper seed placement. Seed is not broadcast behind the disc opener.

- EZ-OFF depth bands on every double disc control planting depth. Shallow planting is required for most grass and legume species. A shallow, uniform planting depth results in a uniform seedling emergence. Depth bands are available in four sizes depending on the desired planting depth and soil texture.

- Scrapers on the disc openers and the depth bands keep moist soil from building up and affecting planting depth and seed placement.

- Press wheels operate independent from the planter assembly. The press wheels on Truax Drill track directly behind the disc openers to firm and press the soil around the newly planted seed without controlling the depth the planting unit is operating.

- Interseeding or no-till drilling in crop residue or sod is easily accomplished using the concave, notched, fixed mount Trash Plows, or the optional 24 or 13 wave coulter on a caster style mount.

- End wheel drive powers the seed metering mechanism to assure a constant flow of seed to the disc openers under all planting conditions.

- A tongue style hitch easily converts to three-point style by adding Category 2 or 3 hitch pins to pre-drilled holes in the frame. A folding tongue is an option for ease of transport and storage.

TRUAX – we have continuous improvement to the Truax line of drills to better meet the challenges of the owners and operators of the FlexII Series of drills, Trillions, and Pull Broadcasters. Insist on the following “features” when selecting a drill for your next project.

FLEXII GRAIN DRILLS – END WHEEL DRIVE

- Two metal pin agitators per metering seed cup on grain drill prevents material above the fluted feed rolls from bridging and blocking the flow through the seed passage.

- Speed changer with 5 sprocket derailleur provides coarse adjustment of output.

- Grain seed metering cups have double spouts to direct seed to front or rear rank of drills having staggered planters, thereby providing a straight line flow of seed to the disc openers.

- Grain seed metering cups have four (4) settings for the seed flow gates to help eliminate scraping or cracking of seed.

- Seed delivery from all seed boxes is between double discs.

- Row spacing is 7-13/16″ between planter assemblies.

- Seed placement and depth is controlled by metal depth bands on all disc blades.

- 1.75″ X 10″ “V” press wheels firm soil in “V” slot created by disc opener. Press wheels operate independently from planter assemblies – one can rise and the other may follow, or go in opposite direction.

- Auger agitators in fluffy seed box move and stir the seed bidirectionally to prevent bridging and plugging of the seed way passage.

- Metal row dividers in small seed box and fluffy seed box keeps the seed in contact with the seed metering wheels in order to maintain constant seed delivery.

- Two metal pin agitators per metering seed cup on the cool season/grain box prevents bridging of material above the fluted feed.

- Mud scrapers to clean vertical disc blades.

- Mud scrapers to clean between disc blades.

- Mud scrapers to clean horizontal depth bands.

- Optional depth bands, four sizes in addition to the standard, for different species planted in to differing soils.

- Optional dual rear transport assembly for towing the drill and to raise it vertically to 12″ to 14″ ground clearance for transport.

- Optional folding tongue to reduce the drill size for trailer transport to less than 102″, front to back.

- Optional row dividers for the cool season box to maintain uniform seed flow when working on side slopes.

- Optional staggered planters and no-tills for improved trash clearance when no-tilling.

- Optional output reduction kit to reduce seed flow.

- Optional no-till for planting in to residue.

- Optional cool season box for sowing slick grain type seeds.

- Optional tail lights for improved safety while traveling on roadways.

- Optional walk boards for improved access to fill seed boxes.

FLEXII GRAIN DRILLS – THREE POINT HITCH

- Maneuverability in small, restricted areas.

- Single or double driving wheel in center of rear of drill makes the Utility the narrowest profile Truax drill.

- Seed delivery from all seed boxes is between double discs.

- Row spacing is 7-13/16″ between planter assemblies.

- Seed placement and depth is controlled by metal depth bands on all disc blades.

- 1.75″ X 10″ “V” press wheels firm soil in “V” slot created by disc opener. Press wheels operate independently from planter assemblies – one can rise and the other may follow, or go in opposite direction.

- Auger agitators in fluffy seed box move and stir the seed bi-directionally to prevent bridging and plugging of the seed way passage.

- Metal row dividers in small seed box and fluffy seed box keeps the seed in contact with the seed metering wheels in order to maintain constant seed delivery.

- Two metal pin agitators per metering seed cup on the cool season/grain box prevents bridging of material above the fluted feed .

- Mud scrapers to clean vertical disc blades.

- Mud scrapers to clean between disc blades.

- Mud scrapers to clean horizontal depth bands.

- Optional depth bands, four sizes in addition to the standard, for different species planted in to differing soils.

- Optional row dividers for the cool season box to maintain uniform seed flow when working on side slopes.

- Optional staggered planters and no-tills for improved trash clearance when no-tilling.

- Optional output reduction kit to reduce seed flow.

- Optional no-till for planting in to residue.

- Optional cool season box for sowing slick grain type seeds.

- Optional tail lights for improved safety while traveling on roadways.

- Optional walk boards for improved access to fill seed boxes.

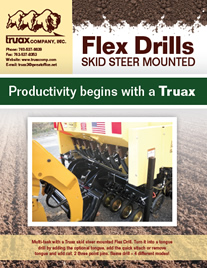

FLEXII GRAIN DRILLS – SKID STEER MOUNTED – END WHEEL DRIVE

- Maximum operator visibility when planting restricted areas.

- Two (2) sets of hydraulic disconnects to facilitate changing from skid steer mount to three point or to tongue style.

- Reinstalling tongue to front of drill makes drill a towed, end wheel style of unit.

- Seed delivery from all seed boxes is between double discs.

- Row spacing is 7-13/16″ between planter assemblies.

- Seed placement and depth is controlled by metal depth bands on all disc blades.

- 1.75″ X 10″ “V” press wheels firm soil in “V” slot created by disc opener. Press wheels operate independently from planter assemblies – one can rise and the other may follow, or go in opposite direction.

- Auger agitators in fluffy seed box move and stir the seed bi-directionally to prevent bridging and plugging of the seed way passage.

- Metal row dividers in small seed box and fluffy seed box keeps the seed in contact with the seed metering wheels in order to maintain constant seed delivery.

- Two metal pin agitators per metering seed cup on the cool season/grain box prevents bridging of material above the fluted feed .

- Mud scrapers to clean vertical disc blades.

- Mud scrapers to clean between disc blades.

- Mud scrapers to clean horizontal depth bands.

- Optional depth bands, four sizes in addition to the standard, for different species planted in to differing soils.

- Optional row dividers for the cool season box to maintain uniform seed flow when working on side slopes.

- Optional staggered planters and no-tills for improved trash clearance when no-tilling.

- Optional output reduction kit to reduce seed flow.

- Optional no-till for planting in to residue.

- Optional cool season box for sowing slick grain type seeds.

- Optional tail lights for improved safety while traveling on roadways.

- Optional walk boards for improved access to fill seed boxes.

FLEXII GRAIN DRILLS – REAR DRIVE

- Twelve to fourteen inches of ground clearance between disc openers and roadway when towing on highways.

- Rear wheel assemblies aligned with trailer ramps when loading for transport.

- 3″ X 8″ hydraulic cylinder replaces spring leveler on tongue to facilitate the leveling of the drill and to change weight transfer from press wheels to the leading no-tills.

- Seed delivery from all seed boxes is between double discs.

- Row spacing is 7-13/16″ between planter assemblies.

- Seed placement and depth is controlled by metal depth bands on all disc blades.

- 1.75″ X 10″ “V” press wheels firm soil in “V” slot created by disc opener. Press wheels operate independently from planter assemblies – one can rise and the other may follow, or go in opposite direction.

- Auger agitators in fluffy seed box move and stir the seed bi-directionally to prevent bridging and plugging of the seed way passage.

- Metal row dividers in small seed box and fluffy seed box keeps the seed in contact with the seed metering wheels in order to maintain constant seed delivery.

- Two metal pin agitators per metering seed cup on the cool season/grain box prevents bridging of material above the fluted feed.

- Mud scrapers to clean vertical disc blades.

- Mud scrapers to clean between disc blades.

- Mud scrapers to clean horizontal depth bands.

- Optional depth bands, four sizes in addition to the standard, for different species planted in to differing soils.

- Optional folding tongue to reduce the drill size for trailer transport to less than 102″, front to back.

- Optional row dividers for the cool season box to maintain uniform seed flow when working on side slopes.

- Optional staggered planters and no-tills for improved trash clearance when no-tilling.

- Optional output reduction kit to reduce seed flow.

- Optional no-till for planting in to residue.

- Optional cool season box for sowing slick grain type seeds.

- Optional tail lights for improved safety while traveling on roadways.

- Optional walk boards for improved access to fill seed boxes.

Specification Tables

FlexII Series End Wheel Drive Drills

| Description | FLXII-88G | FLXII-812G | FLXII-816 | FLXII-818G | FLXII-822G | |

| Row Spacing (# of Openers) | 8″ (8) | 8″ (12) | 8″ (16) | 8″ (18) | 8″ (22) | |

| Seeding Width (ft) | 5.3 | 8.0 | 10.5 | 12.0 | 15.0 | |

| Weight (lbs) | 1500 | 2000 | 2500 | 3000 | 3500 | |

| Weight (w/ no-till) | 2060 | 2840 | 3620 | 4260 | 5040 | |

| HP Required (w/o no-till) | 30 | 40 | 50 | 60 | 75 | |

| HP Required (w/ no-till) | 40 | 50 | 60 | 75 | 100 | |

| Seed Box Capacity (Bushels/Foot): | ||||||

| Small Seed (Legume) | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | |

| Jumbo Grain | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | |

Options

| Acre Meter – Mechanical/Electronic | No-Till |

| Output Reduction Kit | Manual Hydraulics |

| Spare Tire Mount – Lockable | Folding Tongue |

| Grain Box Row Dividers | Caster Wheel – Front |

| Footboard Brackets & Bolts | Covering Chains |

| Open Grid Grate Walkboard w/step | Tool Box – Lockable |

| Rear Transport Wheels – end wheel only | Tail Lights |

| Rear Jack Stand – end wheel only | Safety Chain |

| Dual Rear Drive – rear drive only | Staggered Disc Openers |

| Tires: | |

|

|